Damaged Insulated Panel Ceiling:

We can design and install a Stainless Steel support system for any existing Insulated Panel Ceiling.

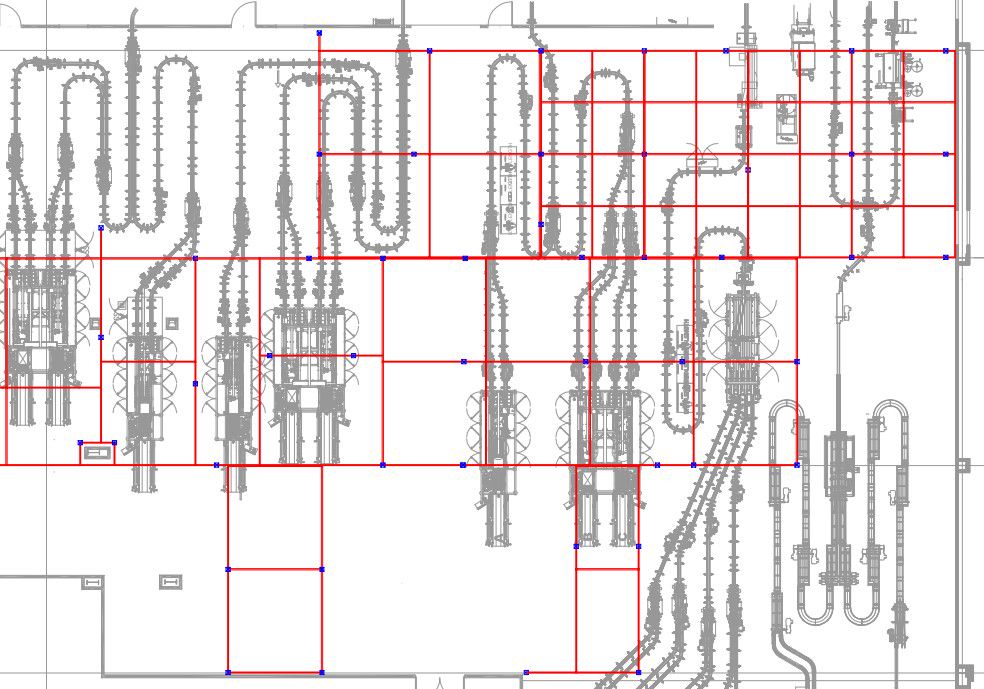

Project Example: Trolley Loading area water damaged ceiling in large scale milk bottling plant:

As an alternative to complete replacement of the panels which would have required investment of >£1m and lengthy shutdowns across 6 production lines over a period of 6 months we designed and installed a Stainless Steel support structure.

The structure was installed during normal production with short outages when beams were being installed over running lines.

Bespoke lifting equipment was developed in order to lift the Stainless Steel horizontal beams into position.

The structure was designed with support from our Structural Engineer who helped us develop an adjustable height system which could be used to adjust the ceilings back to the correct height and level where it had become deformed due to water damage.

Each leg of the framework incorporated an adjustable foot which was used for levelling then a ‘boot’ was used to seal in the adjustable foot and fillet welded around the top to seal.

On completion the area above the ceiling became a walk-on void capable of supporting maintenance access and services.

In total an area of around 250 square metres was supported and this work was completed over a period of 4 months.

This was at a cost of less than 20% of the alternative quoted cost of a replacement ceiling and with no significant production outages required.

If you have a similar project you would like quoting please get in touch.